The machine commonly used to make concrete blocks is called a concrete block making machine. This machine is specifically designed for the production of concrete blocks, which are widely used in construction for building walls, pavements, and other structures.

Concrete block making machines come in various types and sizes, ranging from small manual machines to large automated systems. The most common types of concrete block making machines include:

Manual Concrete Block Making Machine: This is a simple and low-cost machine that requires manual operation. It is typically used for small-scale production and is manually operated to produce individual concrete blocks.

Semi-Automatic Concrete Block Making Machine: This machine has a semi-automated operation, combining manual and automated processes. It requires manual loading of raw materials and the operator controls the machine to carry out the block-making process.

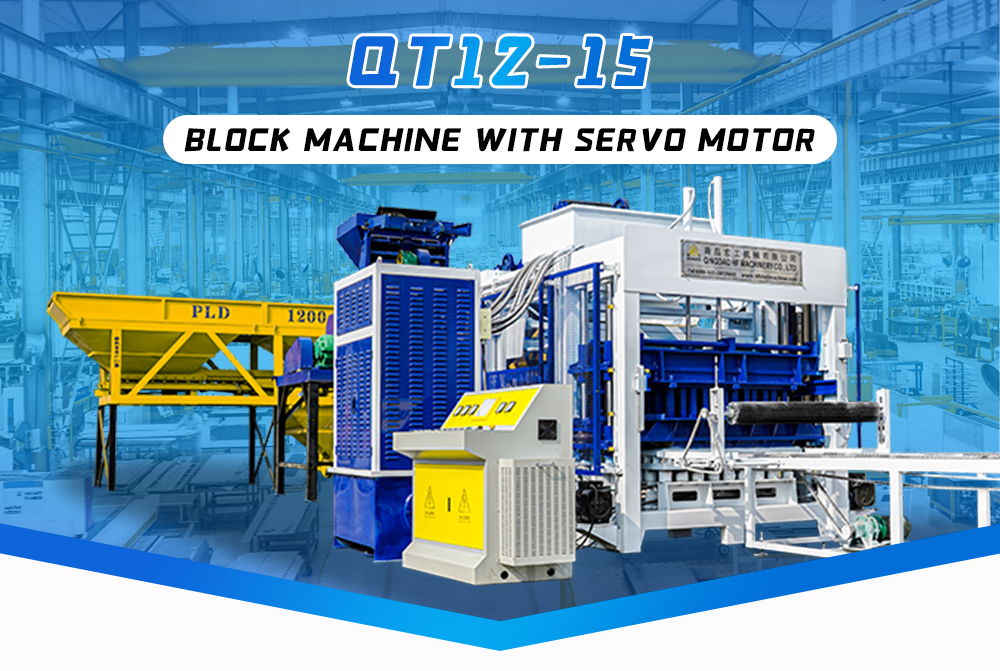

Fully Automatic Concrete Block Making Machine: This is a highly automated machine that performs all the processes automatically, from raw material feeding to block formation and stacking. It offers high production capacity and efficiency.

Concrete block making machines usually utilize a combination of hydraulic pressure, vibration, and compression to mold and solidify the concrete mix into the desired block shape. The machines can produce various types of concrete blocks, including hollow blocks, solid blocks, paving blocks, interlocking blocks, and more, depending on the mold configuration.

.jpg)

It's worth noting that the specific features and capabilities of concrete block making machines can vary based on the manufacturer and model. Therefore, it's important to consider your specific production requirements and consult with manufacturers or suppliers to choose the most suitable machine for your needs.

Back To The List

Introduction and advantages of three types of fully automatic block machine maintenance lines

In Africa, the use of bricks for construction varies widely depending on regional availability, climate, and historical factors.

As the Dominican Republic's economy rapidly develops, the demand for precast concrete blocks across various sectors within the country is steadily rising. Precast concrete blocks are primarily used in two types of construction: ordinary residential buildi

Whether for inquiries for inspections and

maintenance, for individual plant optimizations or

extensions, or spare and wear parts.

Our after-sales service is at your disposal for all

questions

Gemini Tower, Block B, Chunyang Road, Chengyang District, Qingdao, China

Show on the Map

We will contact you within 24 hours.